Wax Coating Enhances Moisture Resistance and Protects Fresh Produce

The Science Behind Wax Coating in Fresh Produce Packaging

Boxes coated with wax form a water-repelling layer that keeps liquid out but still lets some moisture escape as vapor. The coating process involves saturating the cardboard's tiny pores with either paraffin wax or plant-based alternatives, which cuts down on water uptake by around 90 percent compared to regular boxes without any treatment. What's interesting is how this wax actually makes the corrugated cardboard stronger too. Even in really humid conditions where the air holds over 85% relative humidity, these waxed boxes hold their shape and don't fall apart like untreated ones would under similar circumstances.

Managing Moisture From Washing, Condensation, and Transpiration

When fresh fruits and veggies are stored, they tend to create moisture in several ways. First there's leftover water after washing them at the farm. Then comes condensation when they're shipped in cold trucks, and finally there's the natural way plants release water vapor as part of their normal process. To keep boxes from getting soaked, manufacturers apply wax coatings that actually push water droplets toward the edges instead of letting them soak into cardboard. Most packaging also has small holes punched in specific spots throughout the container. These let air circulate properly so water doesn't pool up inside.This effect is also quite significant - studies have shown that this simple design can reduce mold problems in delicate foods such as strawberries or spinach by one-third to nearly two-thirds. This has a huge difference in maintaining food safety for a longer period of time before it reaches the store shelves.

Preventing Water Damage and Spoilage During Cold Chain Transit

When temperatures swing around in cold storage chains, condensation becomes a real problem. Think about it: just one pallet of fresh produce can actually release around 1.5 liters of water each day from all that moisture buildup. That's why wax coated boxes are so important for keeping things intact. These special boxes hold up much better when temps drop to about minus five degrees Celsius, something regular cardboard just can't handle without falling apart in humid conditions. The extra strength means these boxes don't collapse under pressure when stacked together during those long 72 hour transport periods, maintaining their ability to protect what's inside throughout the whole journey from warehouse to store shelves.

Maintaining Produce Quality With a Reliable Water Vapor Barrier

Wax coatings work wonders for extending shelf life because they strike just the right balance between keeping moisture in and letting it out when needed. Tests have found that these wax lined boxes can keep internal humidity levels around 85 to 92 percent, which is pretty much perfect for stopping apples and stone fruits from drying out while also making it harder for bacteria to grow on tomatoes and peppers. What makes this technology so effective is the way the wax forms what scientists call a semi permeable barrier. This actually cuts down on fruit respiration rates somewhere between 18 and 25 percent, meaning fruits stay fresh longer without needing those fancy modified atmosphere packages that cost extra money.

Structural Benefits of Wax-Coated Corrugated Boxes in Logistics

Reinforcing Cardboard Strength Through Wax Lamination

When wax is applied to regular corrugated boxes, it actually forms a protective layer on those cardboard fibers. This process fills in all those tiny little gaps between fibers and creates something like a solid wall against moisture and physical damage. Regular boxes without this treatment tend to fall apart pretty quickly when they get wet. But wax coated ones? They hold up surprisingly well even in cold storage areas. According to research from Packaging Materials Journal back in 2023, these wax treated boxes keep about 92% of their original strength when stored in refrigeration units. That makes them especially good for fruits and vegetables that need to stay consistently chilled throughout transport and storage.

Improved Impact Resistance and Stacking Durability in Refrigerated Transport

The flexibility of food-grade wax prevents cardboard brittleness at low temperatures, allowing boxes to absorb impacts from pallet collisions without tearing—especially important for fragile fruits like peaches and tomatoes. Refrigerated warehouse studies show wax-coated containers withstand 25% higher stacking pressures than untreated alternatives, reducing crush damage by up to 18%.

Data Insight: 40% Increase in Compression Strength With Wax-Coated Boxes

Compression testing reveals wax-treated corrugated boxes achieve 286 lbs/in² crush resistance versus 204 lbs/in² for standard boxes. This 40% improvement supports safer multi-modal shipping, with wax boxes maintaining load stability through an average of 3 transloading cycles compared to 1.8 for regular containers.

Supporting Supply Chain Efficiency With Durable Wax Box Packaging

The extended lifespan of wax coated boxes has reduced the replacement demand in the agricultural product logistics network by 30-50%. Its oil resistant surface allows direct contact with wet agricultural products without adhesive failure, simplifying packaging operations. These durability features help distributors avoid 22% of cold chain interruptions caused by traditional box failures.

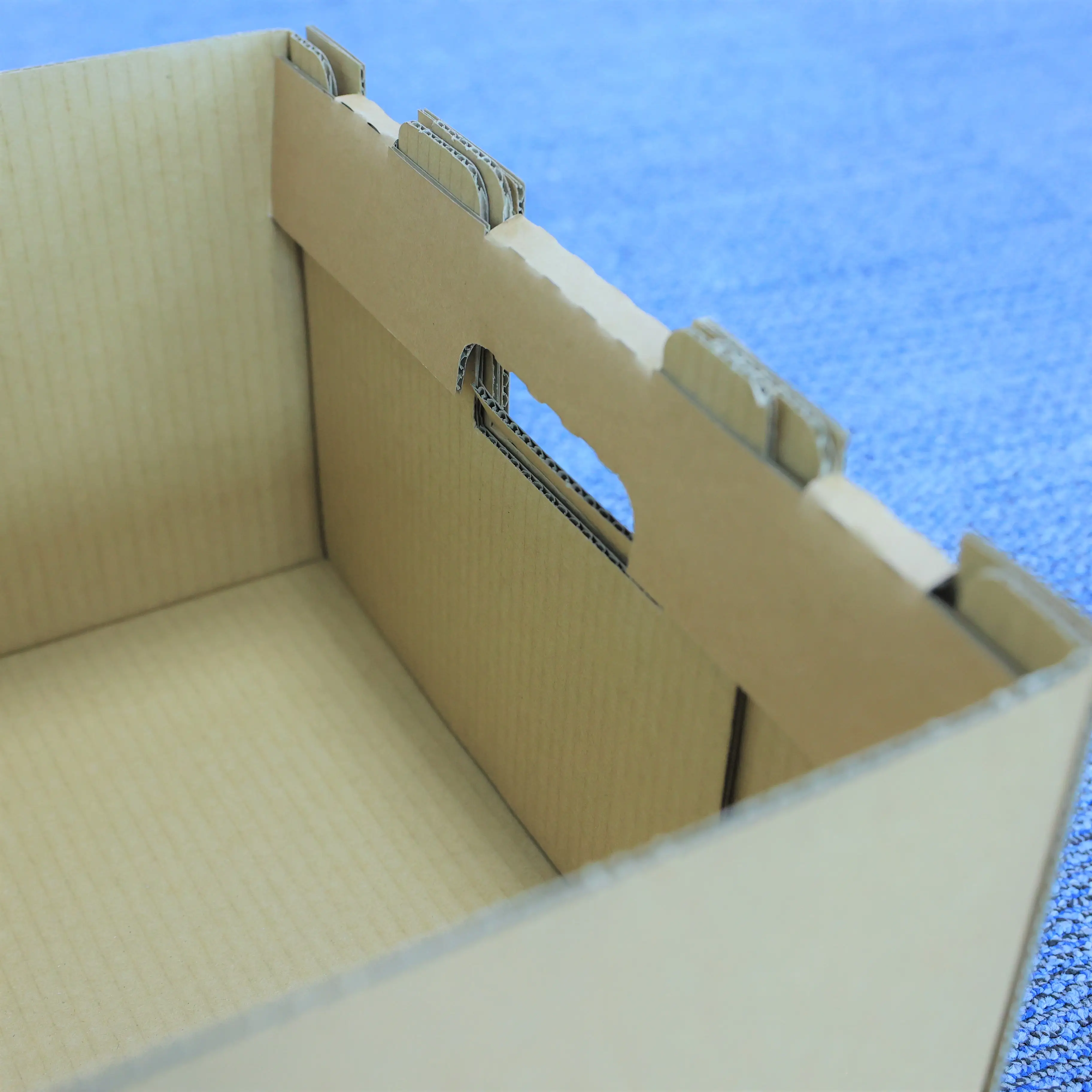

Ventilation Design in Wax-Coated Boxes for Optimal Freshness

Importance of Pre-Punched Vents for Airflow in Sealed Environments

The wax box packaging keeps fruits and vegetables fresh longer because of those little ventilation holes we see on the sides. These aren't just random openings but carefully positioned to fight off moisture buildup caused when produce breathes. According to research published last year by Cold Chain Logistics experts, around one third of all moisture problems inside sealed containers comes from condensation and plant respiration. The pre-made vent holes allow air to move naturally through the package, helping get rid of excess water vapor while still keeping the wax coating intact and waterproof. This balance between airflow and protection makes a big difference in shelf life for perishable goods during transport and storage.

Balancing Moisture Control and Air Circulation to Prevent Mold

Optimal vent density ranges from 2% to 5% of total surface area, depending on produce type:

| Produce Type | Recommended Vent Coverage | Humidity Retention Benefit |

|---|---|---|

| Berries | 2.5%-3.5% | Prevents mold |

| Leafy Greens | 1.8%-2.2% | Reduces dehydration |

| Citrus Fruits | 4.0%-5.0% | Controls condensation |

This balance can prevent fungal growth while maintaining a relative humidity level of 85-95%, which is crucial for freshness (Postharvest Biology Review 2023).

Smart Vent Placement Extends Shelf Life for Berries and Citrus

Lateral vent positioning proves 40% more effective than top-only designs for soft fruits, according to USDA trials. Angled lower vents create convection currents that carry ethylene gas away from strawberry containers, extending marketable shelf life by 3–5 days compared to non-ventilated wax boxes.

Avoiding Over-Ventilation and Moisture Loss in Delicate Produce

During the 7-day refrigeration process, excessive ventilation can result in a quality loss of 12% -18% for spinach and vanilla (Agricultural Packaging Journal, 2022). Compared with traditional 5mm circular ventilation openings, laser perforated micro ventilation openings (diameter 0.5-1.0mm) can maintain airflow while reducing water leakage by 60%.

Extending Shelf Life and Supporting Post-Harvest Management with Wax Boxes

Extending shelf life through microclimate control in wax box packaging

Boxes coated with wax actually form something like a mini climate inside that cuts down on oxygen getting in and out by around 18% when compared regular old cardboard according to research from Postharvest Biology and Technology last year. What happens next? Well, fruits and veggies that get ripe fast because they react to ethylene gas slow down their aging process significantly. Think strawberries or spinach here. The water resistant layer keeps things pretty moist inside too, holding humidity levels between about 85 to 90%. That's just right for keeping apples plump and roots vegetables fresh without letting mold start growing everywhere. And here's another plus point over traditional modified atmosphere packaging methods: these wax boxes work all on their own without needing special machines to pump gases in or out. Just simple passive protection against spoilage.

Preserving cold chain integrity with waterproof and grease-resistant wax boxes

When moving goods under refrigeration, wax boxes stop about 92% of moisture from getting absorbed compared with regular cardboard boxes according to a study published in International Journal of Refrigeration back in 2023. These boxes have surfaces that don't soak up fruit oils or veggie juice which tends to break down normal cardboard over time. This becomes really important for those long hauls where citrus fruits or avocados might sit for weeks inside shipping containers. Because they last longer, these wax boxes work well throughout different stages of cold storage operations. Think about tomatoes being cooled down after harvest then peas needing quick freezing later on all while keeping the packaging intact. Some big farming operations have noticed around 32% drop in rejected crops since switching to these wax coated containers for storing their freshly picked produce before delivery.

Industry challenge: Performance vs. compostability trade-offs

Most fruit and vegetable exporters still go with wax boxes when shipping their goods, despite the fact that barely a quarter of city recycling centers will take wax coated stuff (Green Packaging Initiative report from last year). The petroleum based waxes that keep fruits fresh so well actually take over a year and a half to break down in landfills, which is obviously not great for the environment. There are these new plant based alternatives coming out that look promising, though they're only about two thirds as good at stopping water vapor compared to regular wax. Farmers find themselves stuck between paying extra cents per box for greener options while also needing those traditional wax boxes because they extend shelf life by around 10 to 15 percent. It's like walking a tightrope between what's better for the planet and what keeps produce selling after it reaches market.

Environmental Impact and Sustainable Alternatives to Traditional Wax-Coated Boxes

Recycling Challenges of Wax-Impregnated Paperboard Materials

The problem with wax coated boxes lies in their mixed material makeup which makes them really tough to recycle. Regular cardboard gets recycled at around 68 percent in America according to AF&PA data from last year, but when there's wax laminated paperboard involved things get complicated. The wax needs special treatment to be separated from the actual paper fibers since it's made from petroleum products. A lot of local recycling centers just throw up their hands and refuse to take these items, so roughly 40% ends up going straight into landfills every year instead. For businesses that depend on wax boxes because they keep stuff dry while still wanting to be environmentally responsible, this presents quite the dilemma between practicality and sustainability goals.

Current Sustainability Practices in Agricultural Packaging Supply Chains

Top suppliers are focusing on two main approaches these days: getting more life out of wax boxes before they're discarded and mixing recycled materials into their fresh packaging designs. Many companies have started working with Forest Stewardship Council certified paperboard coming from sustainably run forests, which has helped cut down on forest clearing by about 15-20% over the past few years according to industry reports. Meanwhile, folks running cold storage facilities are teaming up with local energy recovery centers to turn old wax containers into fuel for factories nearby. While this does help reduce what ends up in landfills, most experts agree it's just a temporary fix rather than something that creates a fully circular system where nothing gets wasted.

Emerging Biodegradable Coatings as Eco-Friendly Alternatives to Wax Boxes

More companies are now turning away from old-school petroleum waxes and experimenting with plant-based alternatives that work just as well but are better for the planet. Recent tests in 2023 showed some interesting results too. Chitosan coatings made from crab and shrimp shells actually held up against water pretty much the same way regular paraffin wax does. And get this - when they mixed starch films with walnut extract, berries stayed fresh 12% longer than usual. The really cool part? These eco-friendly packages break down completely within 6 to 12 weeks if tossed into an industrial composter. Compare that to traditional wax coatings which can take over half a century to disappear from landfills. Makes you wonder why we waited so long to make the switch, doesn't it?

Future Outlook: Balancing Performance, Cost, and Environmental Responsibility

What's really challenging for this industry right now is balancing three things at once: keeping those wax boxes effective as protectors, cutting down on production costs, and making them better for composting. Some companies have started experimenting with mixed approaches that put thin wax coatings together with cellulose nanofibers as reinforcement. These pioneers are seeing around 30 percent less material needed while still getting good results from their packaging solutions. With stricter regulations coming down from places like Europe through updated packaging laws, research teams are working hard on developing closed loop systems. Basically they want to find ways to recover and reuse those coating materials using enzymes instead of just throwing them away after one use.

FAQ

What are the benefits of using wax-coated boxes for fresh produce?

Wax-coated boxes enhance moisture resistance, prevent water damage, and help maintain the structural integrity of the boxes. They provide a water-repelling layer that allows some moisture to escape while keeping out excess water, ensuring that fresh produce stays in optimal condition during storage and transport.

How do wax coatings extend the shelf life of fresh fruits and vegetables?

Wax coatings form a semi-permeable barrier that helps maintain the ideal humidity levels and reduces respiration rates of fruits. This balance in moisture control ensures fruits and vegetables stay fresher longer without needing modified atmosphere packaging, cutting down on spoilage.

Are there any environmental concerns with using wax-coated boxes?

Yes, traditional wax coatings are challenging to recycle and often end up in landfills. They take a long time to decompose because they are made from petroleum products. However, there are innovative biodegradable alternatives being explored that provide similar protection with less environmental impact.

Why are ventilation designs important in wax-coated boxes?

Ventilation designs in wax-coated boxes allow for airflow, preventing moisture buildup and mold. Proper vent placement helps maintain optimal humidity levels and extends the shelf life of fresh produce during transit and storage.

How are companies addressing sustainability challenges with wax coatings?

Companies are exploring plant-based coatings and materials from sustainably managed forests to replace traditional wax coatings. They are also working on recycling strategies and collaborating with energy recovery centers to minimize waste and environmental impact.

Table of Contents

- Wax Coating Enhances Moisture Resistance and Protects Fresh Produce

- Structural Benefits of Wax-Coated Corrugated Boxes in Logistics

- Ventilation Design in Wax-Coated Boxes for Optimal Freshness

- Extending Shelf Life and Supporting Post-Harvest Management with Wax Boxes

- Environmental Impact and Sustainable Alternatives to Traditional Wax-Coated Boxes

-

FAQ

- What are the benefits of using wax-coated boxes for fresh produce?

- How do wax coatings extend the shelf life of fresh fruits and vegetables?

- Are there any environmental concerns with using wax-coated boxes?

- Why are ventilation designs important in wax-coated boxes?

- How are companies addressing sustainability challenges with wax coatings?