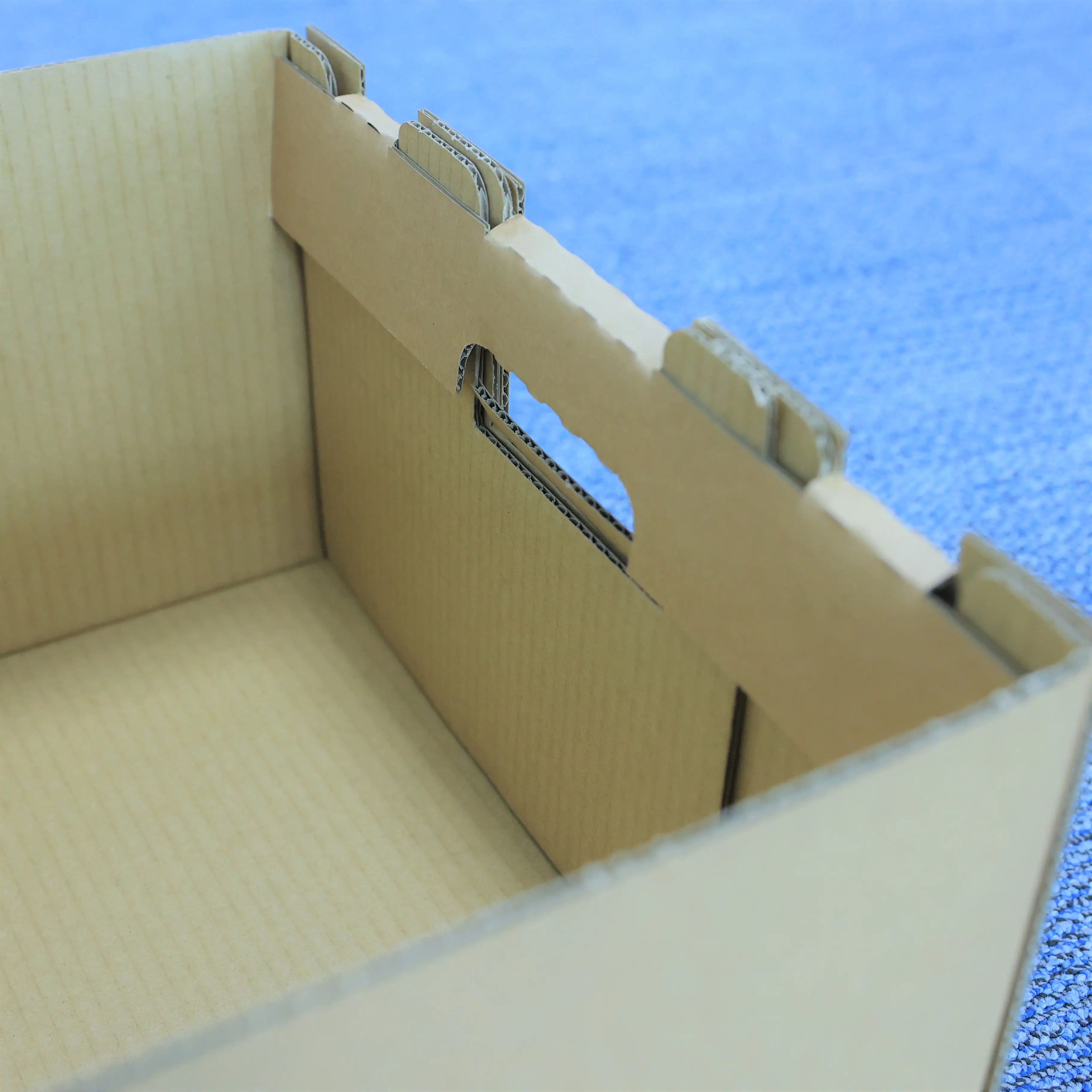

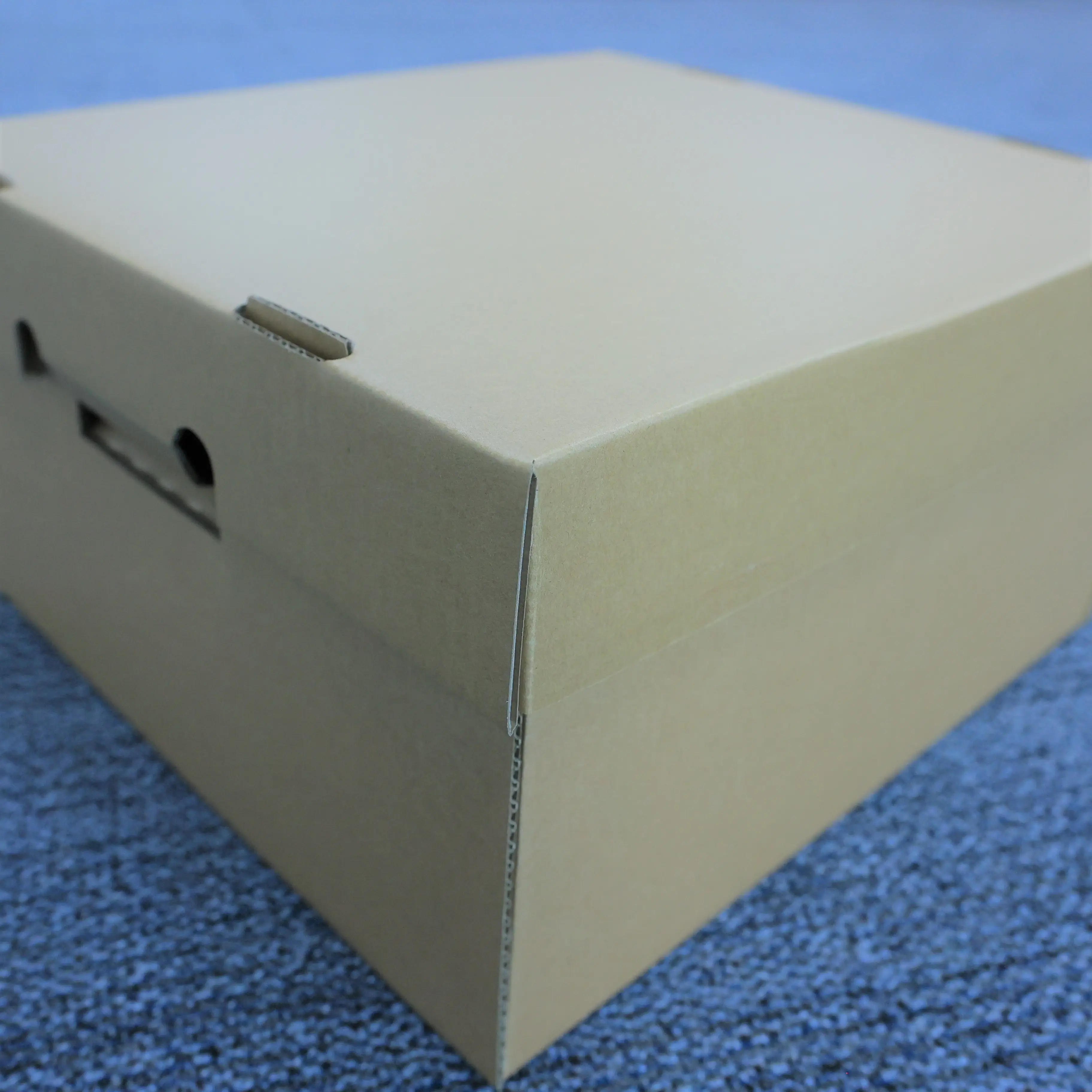

The waxing box refers to a specialized packaging solution where the base material (typically cardboard, kraft paper, or paperboard) undergoes a waxing process to infuse or coat the surface with wax, creating a barrier against moisture, oil, and external damage. The waxing process is a key distinction—unlike standard wax coated boxes that have a thin surface layer, the waxing box often features wax infused into the material fibers (via dip coating or pressure coating) for deeper, long lasting protection. This infusion ensures the box retains its barrier properties even if the surface is slightly scratched or damaged, a critical advantage for high use or shipping applications. The wax used is either food grade (paraffin, microcrystalline, or beeswax) for edible contents or industrial grade wax for non food items, with food grade variants complying with FDA 21 CFR Part 172.886 and EU 10/2011. The base material is selected for strength, with kraft cardboard (350 450 gsm) being common for its rigidity and eco friendly profile. Design features of the waxing box include reinforced seams (sealed with wax for extra protection), foldable structures for easy storage when not in use, and customizable closures (from simple tucks to secure snap locks). Sizes range from small 12x10x6 cm boxes for individual food items to large 55x45x30 cm boxes for industrial parts or bulk produce. Some designs include anti slip surfaces (created by a textured wax coating) to prevent stacking instability during shipping. Application scenarios: in the agricultural sector, they transport root vegetables like potatoes and carrots, protecting them from soil moisture and rot; in the automotive industry, they store small engine parts, repelling oil and preventing corrosion; in the catering industry, they hold large batches of prepared food, resisting grease and maintaining box integrity. A practical case involves a potato farm that used the waxing box for shipping its harvest to grocery chains. The wax infused cardboard prevented soil moisture from warping the boxes, and the durable structure withstood stacking in delivery trucks, reducing box damage by 40%. Another example is an auto repair shop that stored small engine gaskets in the waxing box— the oil resistant wax kept the gaskets clean and free from contamination, improving their performance when installed. For businesses needing packaging with robust, long lasting barrier properties, the waxing box offers superior protection. Interested parties are invited to contact us to learn about waxing process details, material options, and custom sizing to meet specific industry needs.