How Wax Coated Boxes Protect Frozen Food from Moisture and Freezer Burn

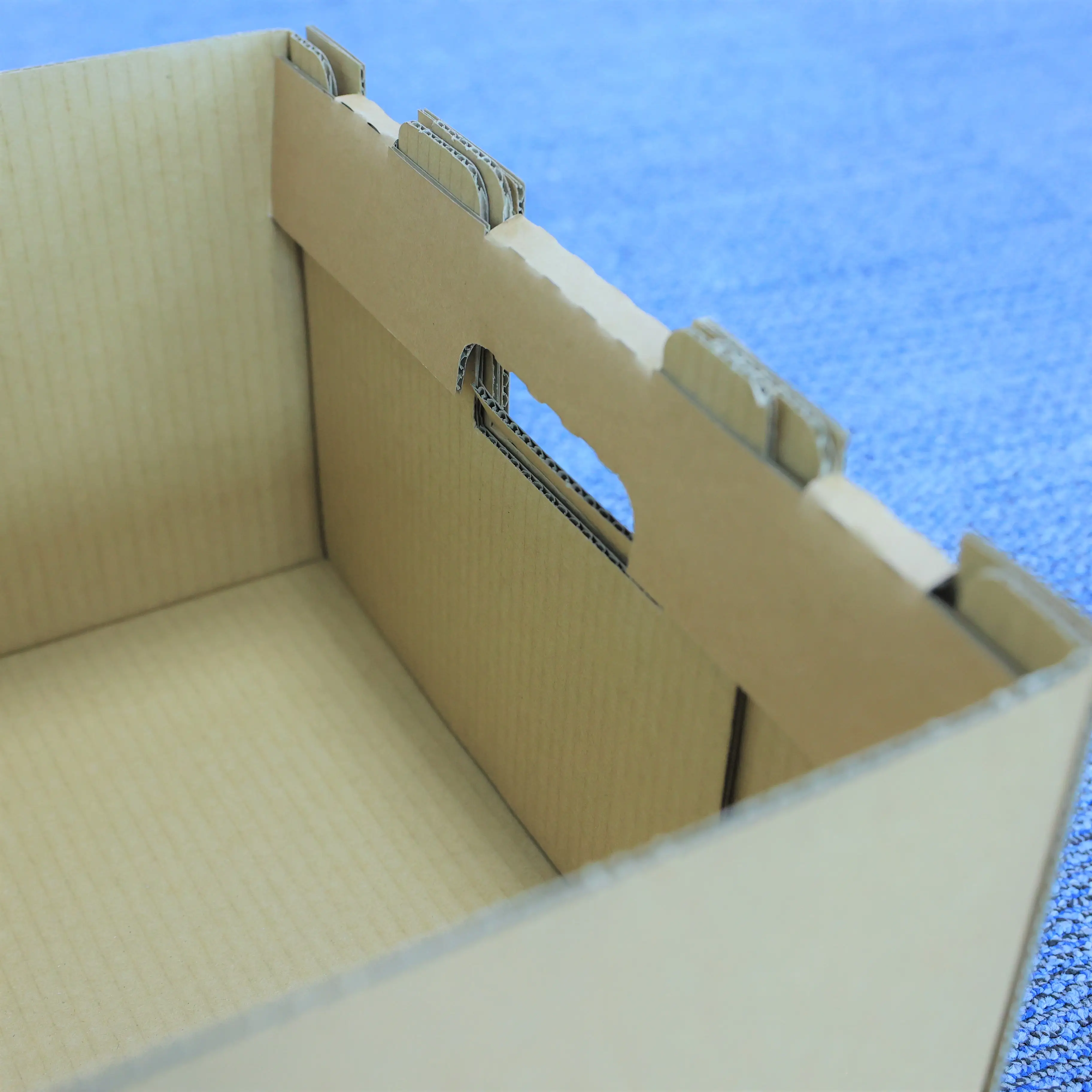

Understanding Wax Coated Cardboard and Its Structure

When making wax coated cardboard, manufacturers mix either paraffin or plant derived waxes into the corrugated fibers to create something that won't easily get wet. The process works because during production, the wax actually soaks into those fibers, forming a kind of water repelling barrier on the surface. What makes this material special though is how it keeps things breathable despite being water resistant. For folks who package frozen foods, this characteristic matters a lot since these packages need to handle all sorts of moisture from condensation and also survive when they go from freezer cold to room temperature quickly without falling apart or getting soggy.

How Wax Coating Creates a Waterproof and Air-Resistant Barrier

Wax coating acts like a protective shield for packaging materials. It keeps outside moisture away while also preventing the contents from drying out too much. Regular cardboard just falls apart when it hits those freezing temperatures in storage facilities, but wax treated boxes handle the cold much better. When moisture comes into contact with these waxed surfaces, it forms droplets and slides right off instead of soaking in. What makes this really important for food producers is how the wax barrier cuts down on oxygen getting through. Less oxygen means slower oxidation processes inside the package. And we all know what happens when frozen foods start oxidizing – flavors fade, textures change, and overall quality drops significantly over time.

Preventing Freezer Burn with Effective Moisture and Oxygen Protection

When food gets freezer burned, it's basically because moisture escapes and oxidation happens when exposed to air. Wax coated boxes help fight this problem in two ways they keep the moisture inside and block out oxygen. According to some recent studies done by the Packaging Research Institute last year, these special boxes cut down on freezer burn about half as much as regular cardboard does. And guess what? They also make things last longer in the freezer around 2 to 3 extra months if kept at consistently cold temperatures. Pretty impressive for something so simple right?

Durability and Performance of Wax Box Packaging in Cold Chain Logistics

Maintaining Structural Strength in Humid and Sub-Zero Environments

According to the Cold Chain Institute report from 2023, wax coated boxes still hold about 92% of their original compression strength even after sitting in 95% humidity for three full days. That makes them roughly three times better than regular cardboard without any treatment. What happens is the wax gets into the fibers and stops them from getting completely soaked, so these boxes work well whether they're stored in freezing warehouses or moved around in refrigerated trucks. The boxes just don't fall apart or lose their ability to stack properly when going through all those temperature changes during shipping.

Enhanced Stacking Strength and Puncture Resistance During Transport

Tests show that this special coating makes the box walls about 18 percent stiffer, which means they can be stacked as high as 8.5 meters in those big automated warehouses according to Package Performance Quarterly. What's really important for businesses is how these containers handle sideways impacts too. They stand up to around 30% more force than regular boxes, something that matters a lot when moving those heavy 1.2 ton pallets around with robots. And there's another benefit nobody talks about much but it counts for a lot in cold storage situations. The surface repels water so ice crystals don't get inside where they would eventually puncture the container during those long trips across country in refrigerated trucks.

Real-World Data: 40% Reduction in Package Failure With Wax Coating

Looking at data from over 4.7 million frozen seafood shipments reveals some impressive results for wax-coated packaging. Leakage problems dropped by around 43%, compression issues went down 39%, and product rejection rates fell dramatically at 52%. According to a study published in Global Logistics Review last year, businesses switching to these wax-based systems saw their cold chain insurance costs drop by approximately 27%. What makes wax so effective? Plastic liners tend to trap moisture inside, but wax allows just enough vapor to escape while keeping things moist enough for seafood preservation during transport. This balance helps maintain quality without the damp mess that often ruins shipments.

Key Applications of Wax Coated Boxes in the Frozen Food Industry

Wax coated boxes have become indispensable in preserving frozen foods across industries. Their unique properties address critical challenges in moisture control, temperature resilience, and product integrity during storage and transportation.

Packaging Solutions for Frozen Seafood, Poultry, and Meats

Meats with high fat content tend to break down faster because of things like lipid oxidation and actual physical damage during storage. The wax coating on some packaging liners acts as protection against punctures caused by sharp ice crystals or bone pieces, and it also helps keep moisture inside the product. A study by the Cold Chain Packaging Institute last year found something interesting: when meat was stored in these wax coated packages instead of regular cardboard ones, it kept around 18 percent more moisture after being frozen for three months straight. That makes a real difference in how good the meat looks and tastes when it finally gets used, plus means less waste overall for processors and retailers alike.

Use of Wax Boxes for Perishable Produce Like Frozen Berries

Frozen berries and other delicate foods actually do better when stored in wax coated containers because these create a sort of stable little climate inside. What happens is that the coating acts like a shield against air getting in, which stops those annoying ice crystals from forming again and again. This helps keep the berry cells intact and maintains most of their nutrients too. According to some recent agricultural packaging research from PMA in 2023, fruits and vegetables that experience changes in humidity tend to drop about 22% in market value after just four weeks on shelves. That's why maintaining this kind of protection matters so much for high quality products that need to stay fresh looking and nutritious until they reach consumers.

Case Study: Extending Shelf Life in Long-Distance Frozen Food Transport

One major frozen pizza company saw their shipping losses drop around 40 percent when they started using wax coated boxes for transporting products across continents. Even though these boxes had to handle extreme temperature swings between minus 20 degrees Fahrenheit and 110 degrees Fahrenheit, they kept the inside moisture level under control at less than 85% humidity, which actually gave the pizzas an extra 25 days on shelves before spoiling. Another big plus was that the cardboard no longer fell apart in those damp port areas where traditional boxes would typically disintegrate. This change alone saved them about seven hundred forty thousand dollars each year according to research published in the Food Transportation Journal back in 2024.

Environmental Considerations: Biodegradability vs. Performance in Wax Coated Packaging

Natural biodegradability of wax-coated cardboard

Bio wax boxes, those made from soy or beeswax, tend to break down pretty quickly when placed in industrial composting facilities. Research published in 2024 suggests these containers can decompose anywhere between two to six months depending on conditions. That's a world apart from plastic coated boxes which hang around for literally hundreds of years while slowly releasing tiny bits of plastic into the environment. What happens to natural wax coatings? They get eaten away by microbes over time, turning into nothing but water, carbon dioxide, and regular old organic stuff. No nasty chemicals left behind either, making them much better for landfills or if they somehow end up in our oceans instead of sitting where they belong.

Challenges with synthetic additives and recyclability

When paraffin is mixed with polyethylene, it really gets in the way of proper recycling efforts. Municipal collection programs typically see their recovery rates drop somewhere around 40% when these materials are involved. The environmental impact is even worse too. These composite materials produce between 2.2 and 4.7 kilograms extra carbon dioxide for every kilogram of packaging compared to what we get from plant based alternatives. Regulations make things even harder for recyclers. The USDA requires all wax to be removed before paper pulp can be processed again. But honestly? Most facilities skip this step because removing the wax takes way too much energy and money to bother with.

Comparing waxed vs. plastic-laminated cardboard sustainability

Wax coatings made from plants cut down on carbon footprints by about 30 to 50 percent compared to those plastic laminate stuff we see everywhere else, all while keeping water out just as well. Both options need special handling during production, but there's a big difference when it comes to breaking down in water. Regular plastic takes forever to decompose, somewhere around 300 years maybe, whereas these wax coatings start disappearing after just 24 months. Recent improvements in how we recover fibers mean around two thirds to four fifths of wax coated packaging can actually get recycled again. This makes sense for companies trying to balance good product performance with wanting their operations to be more sustainable, especially important in cold chain storage where packaging plays such a critical role.

FAQ

Why are wax coated boxes important for frozen food packaging?

Wax coated boxes provide moisture and oxygen protection, preventing freezer burn, extending shelf life, and maintaining food quality during storage and transport.

How does wax coating improve the durability of packaging in cold chain logistics?

The wax coating reinforces structural strength, increases stacking capability, and offers better puncture resistance, ensuring the packaging withstands humidity and temperature changes.

Is wax-coated cardboard environmentally friendly?

Yes, wax coated cardboard made from natural sources is biodegradable and more environmentally friendly compared to synthetic alternatives, offering better sustainability while still performing effectively.